Things are on a roll for cheese processing company Flanders Food Productions in Lommel and they are now in urgent need of scaling up their production capacity. It was up to our constructive challengers to realise the first stage in this trajectory: the construction of two cooled warehouses against an existing storage facility. Site manager Ruben Bloemen tells us more about their race against the clock.

The project

From processing cheese, to packaging, to private labelling. Tons of cheese pass through the company premises of Flanders Food Productions on a daily basis. From there, it is headed towards the wholesalers and the retail market.

In other words: countless purchasers that cannot afford to leave their customers in the cold. It was up to edibo to make sure that the site of FFP was in fact continuously cold to guarantee the quality and the elevated production numbers.

Our constructive challengers came particularly into play for:

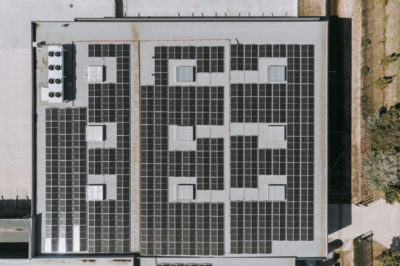

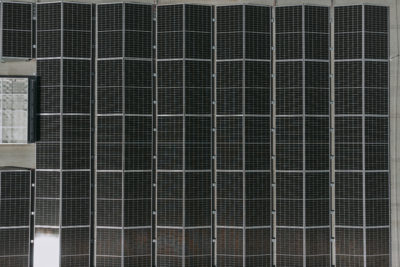

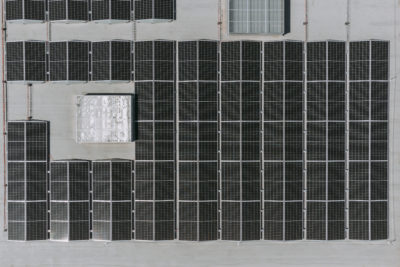

- New construction cooled warehouses against existing warehouse: from building shell to finishing, excluding electrical and cooling installations

- Earthworks and environmental works

- Demolition works of existing parking and construction of new parking lot

We fitted their new cooled warehouses with an in-house office space, loading docks and a large technical space for the cooling installations.

The constructive challenges

There is no edibo project without a number of testing challenges. Ruben Bloemen will lead you through the most important challenges along the way that we were able to combat successfully thanks to our experience and expertise.

A tough start

“During the first stage of the project, we were responsible for the demolition of the existing parking lot. This was located in the location of the new cooled warehouses.”

“But before we could even start with these works, we had to construct two new exterior pavements; on the one hand a new parking lot seen as the existing one would be demolished for the new constructions. On the other hand, an additional concrete pavement to reroute the trucks in order to ensure production continuity during the construction works. We realised all this in no less than a month’s time.”

Warrant continued production flow

“Next, we started with the actual expansion works. We built the new construction part against the existing warehouse façade. We fitted the required openings and gateways into this connecting wall, in order to have easy access between both building parts. In the meantime, we had to make sure that production could go on uninterruptedly and at maximum speed.”

Short but powerful transport

“The newly constructed cooled warehouses consist mainly of steel construction elements and concrete firewalls. Although the steel had to travel no more than 5.1 kilometres from our workshop in Lommel to the construction site, it is always a little nerve-wracking to transport 12 beams of 30 metres.”

Free from dust, sound and … odour

“An expansion in the food industry always bears a number of additional challenges. For instance, noise nuisance and dust formation are an absolute no go.”

“Furthermore, the cheeses could not be contaminated by other odours, such as the smell of fuel released during the polishing of concrete floors. Both building parts therefore needed to be kept completely separate during the expansion works by means of advanced air sealing.”

Small team, finger on the pulse

In this project there was no room for a millisecond of doubting. Thanks to the small project team and the flawless plans of our work planner, we were able to keep our finger on the pulse at all times. We were constantly in close collaboration with the building consultant which means that we were able to share our ideas directly.

Stage 2 of the expansion works – including for instance additional cold chambers and offices – is planned for the near future. We are curious to find out if it is our constructive challengers who can put their strong shoulders under this project!

In the meantime, we are awaiting a new challenge!

Flexibility is one of our parade horses: speed, cooperation possibilities, you name it! Partnering with edibo gives you an industrial construction ally with over 40 years of experience and expertise in the most wide array of industrial industries.

What challenge can you bring to our table? Contact us and reveal your project during a non-binding meeting. We would love to put our ideas up against it. Be sure to take a look at our realisations in your region.